MGB – To B or not to B?

Chapter 2

![]()

- Chapter 2:

- The early years.

- MGB colours.

The first MGB cars built were the convertible model, known also as the tourer, they all shared the same platform and body design throughout the full production run although with many changes taking place. The most significant happening in 1974 when the rubber bumper model was introduced. The early cars are often viewed as the purest as the lines were really clean and uncluttered. The pack away style hood made the car look elegant and smooth as the hood was placed in the boot area, then neither frame nor hood were visible when removed.

The early MGB’s body design was originally built to facilitate the three-synchro gearbox. This was a comparatively narrow transmission unit but did give good space in the cockpit; it was replaced in 1967 with a four-synchro gearbox. Then they needed to widen the gearbox tunnel and modify the body to allow this to fit. It was a better gearbox if a little more snug inside.

The 3-synchro gearbox tunnel fitted to earlier MGBs until the introduction of the 4-synchro gearbox in 1967.

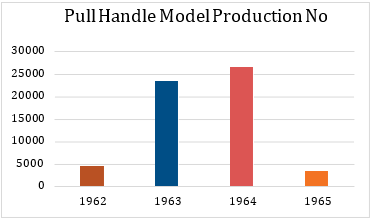

The early cars most recognisable feature was the exterior door handles, they were a pull handle type, very smooth looking. They were replaced in 1965 with the push-button door handles, and these were retained for the remainder of the entire production.

The original exterior pull handle, well known to all MG enthusiasts.

All early cars had the option of either left-hand drive, or right-hand drive form, the hole for the steering column and pedal box mountings were part of the shell making the process very straightforward to build either at the factory.

During the 18-year production run the key market trends dictated how the car developed; the following details list the changes to the exterior of the body and how this affected the appearance of the car, the overall presentation and visual changes. The initial success of the MGB was largely down to its unique styling, it still looks remarkably fresh today. A significant factor put into the design came from Pininfarina who worked alongside MG on several projects. Anyone who has looked at the characteristics of the MGB recognises the importance of the chrome strip, without this one single feature the entire look of the car changes and its definitive lines are lost completely.

Side view of a CCHL MGB Roadster, this angle you never tire of looking at.

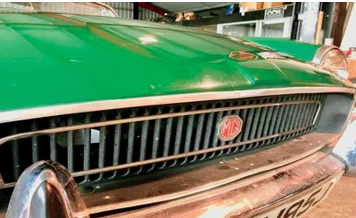

From the full chrome grille with the prominent MG badge proudly sat in the centre, to the smooth flow of the bonnet onto the slightly raked windscreen frame. At the rear the gentle drop of the boot lid, it is an exquisite design that no computer-generated offering could match today. It was in a time long before wind tunnels, and the need for better MPG ruled that artists were given a free reign to sculpt and create beautiful, classic designs that have stood the test of time.

Initially, the body panels were to be manufactured from aluminium, and it was hoped that the doors, boot and bonnet would all be made from the same lighter material, however, with the gauge of the aluminium selected it was decided they dented far too easily. Only the bonnet made it to production; even this was only till 1969 when it went to all-steel to match the rest of the panels, it also helped to reduce the manufacturing costs of the car.

CCHL MGB Roadster finished in a non-standard Aston Martin colour, however, an MGB can pull off most colours with ease.

CCHL Blue MGB Roadster

The early years

Throughout the production run, subtle changes occurred, some to improve the overall aesthetics of the car and others more function over style. From the very first cars changes started to creep in, the radiator chrome slatted grille was changed with the individually riveted slats to a one-piece pressed item from October 1964.

The first significant change was in April 1965 with the introduction of the push-button door handles instead of the pull handle variety.

Later in their life, the early pull handle doors were known for bursting open when the latch started to wear, the newer design eliminated this problem. The body had to be modified as the door catches had different mountings with a more robust latch used, the mountings for the catch on the door casing were altered to match.

MGB tub

CCHL body shell

Door latches and catches

The door locks also changed at this point; the exterior door locks were held in by a spring clip instead of the circlip style of the earlier door locks, this new and improved design stayed with the car for the remainder of the production run. Also, it enabled the boot lock/tailgate lock to match the door locks; now, a single key could operate all three locks.

The new door lock mechanisms were much more durable than the previous design but still retained their good looks. The locking mechanism was also improved; it changed once more in 1967 to allow a different internal opener and lock. The design of the exterior push button door handle was carried onto the MGC and used on the MGB GT V8, and a very similar design was used on the MG Midget.

Internal door opener

The next noticeable design change to the exterior of the car was the addition of reversing lights, this occurred in March 1967 for the Roadster and April 1967 for the GT, they were functional but again lost the pure lines at the rear. Many people thought they cluttered the back panel, but these were essential if MG were to be seen as serious in moving with the times. They also had to keep up to date with its competitors and safety standards too.

Reversing light

Next change to occur was the front wings, this was when the gap for the sidelight and indicator unit was moved closer to the front Grille in September 1968, for the Roadster, and November 1968 for the GT, so all 1969 models had new wings fitted.

Front wing, side light gap change

In 1969 the bonnet was changed from all aluminum items to a steel unit. The rear light units had another significant change; this was also in 1969, all GHN4 and GHD4 cars had the curvier rear light units, these had a backing plate and split rear lenses. There were two pieces, an amber indicator lens and a red rear and brake light lens with a chrome retaining Bezel to hold them all in place. From 69 the GHN/D 5 series was replaced with a squarer unit, this was a one-piece light unit and complete lens which fitted over the backing plate.

Different rear light units

The badges on the MGB were the same throughout the ’60s. Still, during its makeover, in October 69 the boot badge went from the early “MGB” script type with the skeleton octagon badge below to the solid one-piece MG badge on the Roadster, but still with the MGB script above. The GT badge changed from the three-piece MG badge into the solid onepiece, and the “MGB GT” lettering was altered into simple B, GT. Also, British Leyland badges were fitted to the front wings.

The wiper design changed for the 1969 model for the USA market and used three wipers instead of the traditional two that remained on the home market cars. All USA cars were fitted with three wipers until production ended, these proved to be a good idea and did a great job in clearing the rain if caught in a downpour but were never considered for the UK market which retained the two wiper format.

The North American market also saw the rear bumpers change for a limited period for the 1970 model and split rear bumpers used instead of the one-piece type, but this only lasted for one year.

Again for the North American market rear red side markers were fitted on the rear wings and front indicator flashers fitted to the front wings mounted on a black plastic plinth which was profiled to match the contour of the wing to make them sit even. These were fitted on all North American models at this stage and continued through the remainder of production.

Side markers and indicators

Moving with the times – With the MGB selling very well, BMC had no desire to change a winning formula; the company had spent most of the 1960s with a significant shortage of development funds. They were used to enhancing what they had, always making simple revisions to keep things fresh and in line with the moving times.

Nonetheless, the MGB gradually underwent its next transition to appeal to a new audience. The first noticeable change to the exterior and body was the revised grille which was changed from the all chrome slatted version to the recessed black grille with the MG octagon badge perched in the middle with silver letters on a red background.

Black slatted grille

The complete grille was surrounded by an anodised aluminum molding in 4 sections one on the base of the grille insert and two at either side, the final piece attached to the bonnet itself which enveloped the recess when the bonnet was closed. This style of grille lasted less than three years and was replaced in August 1972 with an updated version of the original grille with a chrome surround but with a black mesh insert which was also used on the GT V8 model.

The badge on the grille had also changed its colour from the black background with the red lettering to red background with silver lettering. This grille continued until the end of the chrome bumper cars. It is worth noting that all the grilles on all chrome bumper cars are interchangeable, this is because the aperture is the same size and shape on all the Roadster and GT models throughout the chrome bumper models.

Original pull handle exterior door design

Many owners change back from the recessed style to the all chrome type that makes the car look much older than it is but still favored by the majority for its good looks. During this period the over-riders underwent a small change, at the beginning of 1970 the all chrome over-riders were replaced with a rubber face which acts as a buffer, admittedly they did the job and avoided any marking to the chrome on any small nudges during parking or poor judgment when maneuvering slowly. The North American cars in 1974 saw a rather large black bulky over rider fitted for that year only.

riders Nothing significant changed to the bodywork and exterior of the car until September 1974 when a considerable overhaul occurred. This was the introduction of the infamous rubber bumpers (they were manufactured from polyurethane). Still, everyone was familiar with the term rubber bumpers as they were commonly known as at the time, and indeed they are still called that today. In this same period, a whole host of other changes took place; these are covered in respective sections of the book. Still, the entire look of the car changed at this point; they were installed to maintain the strong market to North America, who was the most significant single buyer of the MGB.

With the ride height raised, and chrome bumpers, sidelights, over-riders gone, the sheer bulk and weight of the bumpers took the edge off the once elegant MGB. Still, surprisingly buyers were not detracted from purchasing too much, and the car continued to be built and sold for a further six years after they were initially fitted. With the chrome bumpers and grille now removed, the overall silhouette of the car was still similar, however, the front view with the larger bumpers covering the space where the front grille sat now had a black mesh panel fitted instead to protect the radiator behind.

Chrome slatted grille

This new front bumper was very deep and covered the front lip of the bonnet with a shaped nose center section for the MG badge to sit. At the rear the bumper was also deep and swept around the rear valence and under the rear light cluster, the design was somewhat bold and did the job very well, as they were extremely sturdy examples they would not have an issue with any small collision.

Still, the look of the car seemed uncomfortable along with the increased ride height, it almost felt like an off-roader in comparison to its prettier and lower riding predecessor. The front wings were altered to its most radical update to allow the indicator lights which were fitted within the bumper itself, to be recessed into the front wing.

Badges

The front valance had to be revised to allow for the alterations, the shape of the front wings were mostly the same, but the front corners chopped and changed for the new requirements. The rear valance was also significantly altered and the large holes for the rear bumper irons and fixings removed. Instead, several smaller holes in the rear valance were used for the mounting of the massive bumper.

Due to the lack of over-riders, the rear number plate lights had to be revised. They were now found on the rear number plate backing that housed the wiring and lamps for the number plate; these were just above the bumper level and below the boot lid.

The rear wings also altered to allow the fitment for the rear bumper and a small section removed where the rear lights mount as the more prominent bumper now curves around in its place and under the rear light units.

It was all done rather neatly and very similar to its smaller relation the MG Midget that saw the same makeover for precisely the same reasons. Following on from this big shakeup in 1974, the year after saw the launch of the Jubilee edition in 1975, celebrating 50 years of MG production. Although some claim it was the 52nd year of production, nonetheless the cars badging changed from silver to gold colour for this year only. The MGB script on the boot lid of the Roadster discontinued, and the large octagon boot badge was now in metal instead of plastic.

The MGB GT saw a limited run of 751 cars built in the unique Jubilee colour scheme of racing Green with a gold stripe and black door mirrors and the wheels were V8 style but painted in gold and black to celebrate the milestone. Each car was individually numbered having its own plaque showing its number in the run. Late in 1975 around December, the front number plate moved slightly to help improve airflow which was something the V8 engine benefitted from.

Wipers

The 1976 model car saw all the badging revert back to the previous color scheme of silver now that the Jubilee celebration was over. In March of 1976, The C post badge was changed to a much cheaper option, and now there was no need to send them to the Cowley plant for lead loading, the bodies could be completed at the Swindon factory saving time and money.

The final major makeover of the MGB occurred in late 1976 when the dashboard was revised along with an overhaul in the engine compartment. The radiator mountings were positioned further forward, the same as the V8 design, the cooling of the engine was improved with electric fans, and the bulkhead design changed for the steering column to sit through, it was now deeper with different mountings along with an altered pedal box.

December 1977 saw the British Leyland badge on the front wing removed, the last hurrah was in August 1980 when the production of the Limited Edition models began for the UK home market, these were supplied with either cast alloy wheels or wire wheels and finished in metallic paint with striping detail down the sides and special red badging, this series ran alongside the standard production run of cars, the US market actually saw these models a bit earlier in the previous year.

MGB Colours

Some unusual and also weird colours were offered on the MGB. Today the most popular shades would include Red, British Racing Green and Old English White as the standout colors for the ‘B’. What many remember most, however, are the various alternatives which were offered, they did suit the shape of the body well but are often overlooked.

The Black Tulip color which made a short appearance in 1973 and Teal Blue that was used again in the early 70’s stand out for me. Colours are a very subjective matter but during the late 70’s even the Russet Browns, and Citron Yellows were a brave choice but were in fashion at the time, allegedly.