MGB – To B or not to B?

Chapter 3

![]()

- Chapter 3:

- The development of the MGB engine 60

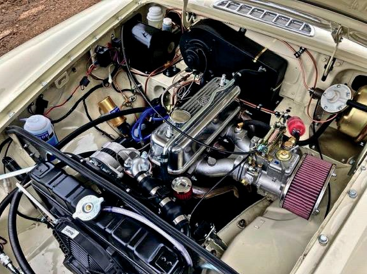

- The 1800cc MGB engine

- The early engine bay.

Chapter 3

THE DEVELOPMENT OF THE MGB ENGINE

The MGB engine has always been known to be a reliable and robust unit. The 1798cc engine was fitted for the entire production run with a few tweaks and alterations along the way, but this was not the first choice of the engine that was used.

BMC initially wanted to use an entirely new type of engine that was based on a V4 design. The V4 motor had a very narrow 18-degree bank angle, and this made the engine very compact. Pushrods still operated valves, but a timing belt drove the camshaft.

BMC had grand ideas to use two four-cylinder versions, one of about 1100cc that would replace the smaller A-series engine and the other around 2000cc that would replace the B-series, there was also mention of a V6 version as well some discussion about the O-series 1.7 litre Marina engine being used towards the end.

The V4 was a corporate project that was developed at Longbridge rather than Abingdon, but Syd Enever was never really comfortable with the idea. V4 engines had been tested in MGA cars before. Still, BMC finally dropped the project in 1960, in the end, they decided that it would be too involved and it could cause production issues.

As this was unknown territory, a long-term view was taken that the new engine format was potentially too risky for a mass-market engine. This idea was eventually put to one side; this then led the way to the very recognisable “B” series engine.

The original basis of the “B” series engine was a 1200 cc Overhead Valve (OHV) engine which was used in the Austin A40 Devon. They realized that eventually they would need an engine that could power many of its upcoming cars and it would need longevity, this would need an engine of much larger capacity of at least 1500 cc. As the A40 Devon engine was not able to have its cylinder capacity enlarged, a new engine would need to be designed and one that would be able to cope with the extra power that would be necessary to help future proof things.

The initial design of this new engine started around early 1952 and was designated as the “B” series. This was very similar but was slightly longer and heavier than the A40 engine. One of the most significant advantages of this unit was that it could be bored out so that the cylinders were increased in size to offer a more substantial capacity. Originally built as a 1200cc then later displacements ranged from 1.2 L to 2.4 L. The most common engine sizes as we now know today were 1500cc and 1800cc; these were to be used in several vehicles for quite some time to come.

1800cc engine bare block

The 1800cc MGB engine

Now that the choice of engine was decided using the robust 1800cc lump, the unit evolved many times. Even today it proves itself to be a worthy power plant for the car with many still going strong (many will have had one or two rebuilds in their lives).

Most, if not all will have been converted to run on unleaded for today’s fuel with the alteration of the valve seats within the cylinder head to accommodate the lower octane fuel we are now using. The engine itself was of conventional construction with a one-piece crankcase and cylinder block in cast iron with the crankcase extending down to the lowest level of the main bearing caps with a cylinder head in cast iron, and a sump made from pressed steel.

The B-Series shares many design features (such as the heart-shaped combustion chambers and Siamese inlet ports) its basic layout and general appearance is similar to the much smaller BMC ASeries engine. However, another difference was its block’s full-depth skirt, which provided excellent bottom-end strength. This made the engine extremely durable and robust as well as being suitable for further development.

The same engine can also be found in Sherpa vans and the Marina, which shared the same basic engine unit, but with differing engine numbers to define what engine went in what car or van. A diesel variation was also looked into as an option; they thought it would be beneficial for many years to come. In the big picture this never happened. The engine that was used on the MGB was the same right through the full production of the 1800cc (1798cc), a big improvement appearing in 1964 when the three bearing crank was upgraded to the five bearing crank engine.

Throughout the production, the engine was updated, when this happened, new engine numbers were used to signify a change for ease of future reference. Many changes were minor, some, merely to the ancillary equipment, although more were implemented to satisfy the North American market than domestic.

Original MGB engine bay with standard air filters

Significant changes to the MGB engine by year |

|

| 1962 | Start of engine production and engine number series |

| February 1963 | New front pulley |

| March 1963 | New outer valve springs and new con rod assemblies |

| December 1963 | Valve cover changed |

| January 1964 | More durable dynamo and new front pulley |

| February 1964 | Closed circuit breathing system, side cover with oil separator, rocker cover with no breather pipe |

| July 1964 | Inlet valve guides updated |

| October 1964 | Updated crankshaft with five main bearings |

| April 1965 | Newer rocker cover now fitted |

| June 1965 | New pistons and rings design now fitted |

| September 1965 | Rocker design changed again electric tachometer now fitted |

| June 1966 | Redesigned water pump used |

| January 1967 | Different thermostat used, new sump |

| February 1967 | High compression pistons and rings fitted |

| August 1967 | New water pump |

| November 1967 | Larger flywheel and ring gear, altered closed-circuit breathing system, new Tecalemit oil filter, thermostat and water elbow changed, block drain tap replaced by a plug. (changeover to 4 synchro gearbox now) |

| March 1968 | New inlet and exhaust valves, new valve springs |

| October 1968 | New style dipstick and dust protector, carburettor crankcase ventilation instead of close circuit system. |

| March 1970 | BL stickers used instead of the plate on rocker covers, new oil filter cartridge. |

| August 1971 | All engines painted black. |

| October 1972 | Single timing chain instead of the duplex chain |

| October 1973 | Spin-on oil filter fitted |

| October 1974 | Rubber Bumper cars with new front engine plate and engine mountings, revised cylinder head with smaller inlet valves, new front cover for engine, new crank pulley, new cylinder front side cover with built-in oil separator. |

| December 1975 | New water pump |

| From 1977 | All these models have electric cooling fans |

1800cc engine, gearbox and overdrive recently rebuilt ready to be installed, this shows how long the 3 units are when combined, it is much easier to fit the engine, gearbox and overdrive together rather than separately.

Engine identification |

|

| 18G | 3 bearing crank, open crankcase breathing |

| 18GA | 3 bearing crank, closed-circuit breathing |

| 18GB | 5 bearing crank, closed-circuit breathing, dynamo |

| 18GD | 5 bearing crank, closed-circuit breathing, alternator |

| 18GG | 5 bearing crank, carb feed breathing circuit, alternator |

| 18GF | USA/Canada only |

| 18GH to GK | |

Engine numbers for quick reference 1962 – 1971 |

||

| Year | Engine prefix | Engine number |

| May 1962 – February 1964 |

18G | 101-21121 |

| February 1964 – October 1964 | 18GA | 101-17500 |

| August 1971 – November 1973 |

18V-581 | 101-5302 |

| August 1971 – November 1973 | 18V-582 | 101-22341 |

| August 1971 – November 1973 | 18V-583 | 101-870 |

| August 1971 – August 1972 | 18V-584 | 101-19491 |

| August 1971 August 1972 | 18V-585 | 101-2751 |

| August 1972 – September 1974 | 18V-672 | 101-38094 |

| August 1972 – September 1974 | 18V-673 | 101-6550 |

| November 1973 – September 1974 | 18V-779 | 101-5359 |

| November 1973 – September 1974 | 18V-780 | 101-7224 |

| September – December 1974 | 18V-836 | 101-5401 |

| September – December 1974 | 18V-837 | 101-1504 |

| September 1974 – June 1976 | 18V-846 | 101-914 |

| September 1974 – October 1980 | 18V-847 | 101-40188 |

| December 1974 – August 1975 | 18V-797 | 101-9361 |

| August 1975 – June 1976 | 18V-797 | 101-10357 |

| December 1974 – August 1975 | 18V-798 | 101-1694 |

| August 1975 – June 1976 | 18V-798 | 101-2007 |

| June 1975 – June 1976 | 18V-801 | 101-14801 |

| June 1975 – June 1976 | 18V-802 | 101-3509 |

| June 1976 – October 1980 | 18V-883 | 101-50984 |

| June 1976 – October 1980 | 18V-884 | 101-10425 |

CCHL Engine bay

The earlier cars all used a three main bearing crankshaft for the 18G-series numbers. In February 1964 positive crankcase breathing was introduced and the engine prefix changed to 18GA, then in October 1964, when a five-bearing crankshaft design was used, the engine prefix became 18GB.

Horsepower was rated at an optimistic 95 bhp on both five-main-bearing and the earlier three-bearing cars with the peak power coming at 5,400 rpm with a 6,000 rpm limit. Torque output on the MGB registered a peak of 110 lb-ft, and fuel consumption was supposed to be around 25 mpg.

Visible changes to the engine; the oil filler cap changed from a metal one to a plastic filler cap and the front side cover on the block included an oil separator which connected the closed-circuit breather control valve on the inlet manifold pipe. The 18G and 18GA engines both used a cable for the rev counter operation whereas the 18GB engines were now electronic.

Next up came the 18GD engine, which was introduced when the MK2 arrived, and the gearbox improved from three synchromesh to the four synchromesh boxes. The 18GF engines were all destined for North America with a few finding their way to Canada.

CCHL MGB engine bay with Weber Carburettor

Many other changes occurred for the export market, and especially for the North American sector. Main ones to note would be the introduction of the evaporative loss control system in October 1969, this was initially for the Californian market which saw its way into all North American cars from August 1970.

US specification cars did see the output power fall and in 1968 the factory introduced new emission standards with the use of smog pumps that drained the power of the car considerably. In 1971 UK specification cars still had 95 bhp at 5,500 rpm, with 105 lb-ft torque at 2,500 rpm.

Engine prefixes became 18V, and by 1973 it was 94 bhp by 1974 it fallen to 87 bhp, with 103 lb-ft torque By 1975 it was 85 with 100 lb-ft.

Some of the California specification cars produced a meager 70 hp by the late 1970s, that made the vehicles pace relatively tame as the carburetor set up was constricted by the stringent emission regulations. The compression ratio was substantially reduced from 9 to 1 to 8 to 1 on USspec cars in 1972.

The early engine bay

CCHL version of early engine bay

The B-series engines all had the 1800 numbering cast into the side of the block on the left-hand side, from 1962 through to 1971 the engines were painted a maroon color. The original engine number would be located on a plate close to where the block meets the head and between number two and three cylinders.

Many MGB engines have been changed over the years, and a reconditioned exchange engine is relatively common. Some reconditioned engines may have their own numbering system that will not correspond to the original factory numbers. The engine was also used in the Marina and Sherpa vans so some may have found their way into an MGB over the years.

The conversion to V8 engines is a popular choice for the power increase and increased torque it offers along with the wonderful sound, it is a tried and tested route which does fit neatly into the MGB engine bay when done correctly. Many other engines have been shoehorned into the MGB, I have seen V6 engines used and even diesel engines fitted along with more modern engines using fuel injection upgrades, however, few seem to deliver the sound and feel of a well-sorted traditional MGB V8 engine.

The 1800cc engine is also good to tune and squeeze some additional bhp out of, stage 2 cylinder heads, better camshaft along with taking the bore up to 2000cc make the car a much livelier machine. The addition of a supercharger is now also available; this makes it a lot of fun and really improves the MGB. It does deliver a significant power boost but always consider you need to stop and go around corners too so, if you increase the power, then other areas also need upgrading.

Overall, the engine choice worked then as it does now, giving adequate performance and reliability in a beautifully simple design without over-complicating anything, and there is little wrong with that.

Later MGB engine bay