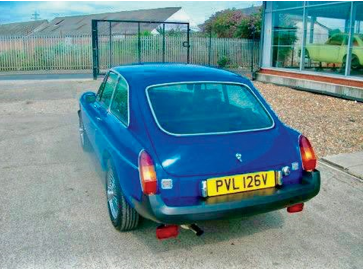

MGB – To B or not to B?

Chapter 7

![]()

Chapter 7

Electrical System

The electrical system on the MGB started life using a positive ground 12V system until 1967 when the negative ground was introduced. Twin 6-volt batteries were fitted in 2 battery trays behind the seats that housed the neat, smaller batteries.

The twin batteries were replaced in 1974 with a single 12Volt battery, which made life a lot simpler for replacement. If the car needed charging or a jump-start, many people were unsure where to put jump leads when they were faced with four possible poles to place the leads on; you can imagine lots of sparks and flashing going on for the inexperienced.

Twin 6V battery placement

Single 12V battery in place

WIRING HARNESS:

The wiring Harnesses was made more comprehensive as additional electrical items were added to the MGB, they were for the most part in two sections, one which ran from the front to the rear to connect everything up from the rear lights to fuel pumps. The main loom incorporated the dashboard section for its controls, lights, and switches that passed through the bulkhead into the engine bay. They connected to the fuse box and alternator through to headlights, indicators, and horns. It was only the later harnesses that had a separate dash harness.

The first wiring looms were cloth bound, later using a PVC covering, the loom changes are below.

| MGB Wiring Harness | |

| 1962/1967 | Positive earth and early cars with Jaeger gauges then moving onto Smiths gauges, dynamo fitted. |

| 1967/1968 | Negative earth cars with an alternator and separate control box |

| 1968/1969 | Alternator with integral control box |

| 1969/1970 | Horn control on the indicator stalk |

| 1970/1971 | The horn back in the centre of the steering wheel |

| 1971/1972 | Radio and additional accessories in the console |

| 1972/1973 | Tachometer change to RVC from RVi |

| 1973/1974 | Hazard warning lights fitted |

| 1974/1976 | First of the rubber bumper cars with Overdrive on the stalk |

| 1976/1977 | Later rubber bumper, O/D on the gear knob, single line brakes, separate dash loom now used MGB Wiring Harness – 1977 Dual-line braking system |

| 1978 | 18 ACR Alternator re-introduced |

| 1979 | Rear fog lamps fitted |

| 1980 | The final change with spade connections for the radiator fans was now used. |

The other additional harnesses available were for the overdrive wiring which ran from the overdrive unit on the gearbox to the bulkhead that then joined into the main loom.

The overdrive harness changed from three synchro cars to three synchro cars with reversing light switches, then onto four synchro cars for the GHN4 cars followed by a change again for the GHN5 cars. A separate harness was installed for the upcoming rubber bumper cars, with the switch for the overdrive on the gear knob.

Wiring Harness with switch on Gear lever.

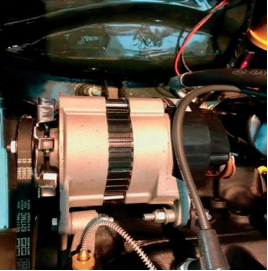

DYNAMO/ALTERNATOR:

Most models from the beginning used a Dynamo; this was sourced from Lucas and was located on the left-hand side of the engine with a control box mounted on the inner wing. An alternator replaced the dynamo in 1967 when the MGB changed to negative earth. The location was in the same place and with a separate control unit, however, in 1969, this changed to a 16 ACR alternator with a regulator built-in. A small change occurred in March 1972 with the 16ACR alternator, with a slightly modified regulator with a surge protection device, but in 1973 this was replaced with a 17ACR unit. Finally, in 1976 an 18ACR alternator was used.

Dynamo and alternator images

FUSE BOX:

The fuse box started life with just two fuses and then was updated to 4 fuses compared to modern cars which have several fuse boxes dotted around a car each with 30-40 fuses in them, it shows the simplicity of the electrical system. The MG didn’t need lots of electrical gadgets and should anything electrical go wrong it was a simple task to remove the fuse box cover and check the fuses in a matter of seconds. Except for inline fuses fitted and a voltage regulator, the system is straightforward to navigate and locate faults. The main reason for failures today is many wiring harnesses become old and brittle, and connectors become loose and/or weak, but back in the day, it proved to be a reliable setup.

The small, neat fuse box housed 4 fuses.

STARTER MOTOR:

Lucas again was used, this time for the starter motor on the MGB and a Bendix drive unit fitted which gives that familiar whirring sound when the key is turned, as it throws itself in to fire up the engine. The changes in 1967 saw the pre-engaged starter motor fitted for the MKII with a starter solenoid switch mounted in the engine compartment. A separate starter relay 6RA was installed for the 1970 model for all 18V engines, during the 1972 period a Lucas 2M100 starter motor was fitted, this ran until the end of production.

LIGHTING:

Headlights, yes they are useful and very much needed, and the MGB was fitted with a pair of 7″ sealed beam units which lit up the road ahead (well sort of) again we cannot compare with modern bright LED lights, I know we all do, but the MGB had sufficient lighting which did the job. Many modern variations are widely available and often used to help aid vision on the narrow country roads that we all like to enjoy driving in a classic MGB.

Standard MGB headlight

The standard headlights changed very little during production with a small upgrade to the sealed beam units for the 1970 model.

The main change was when the headlamp and sidelight were combined for the rubber bumper cars, in June 1976, when they were fitted with H4 headlamps. The actual headlight buckets and wiring were all virtually the same, and each one had the chrome headlight rim surrounding it which covered the adjuster screws and fixing screws and clipped over to finish things off.

The headlight flasher was an option at the start, this became standard from 1965 on all models, and the primary and dipped beam operation was found on a footswitch just to the left of the foot well near the clutch pedal. This was in the same position you would usually rest your left foot while driving. This was remedied in 1970 by the more robust indicator stalk that now operates the headlight flasher and the high beam. The UK market was a little late in using this, as it was adopted onto North American cars from as early as 1967.

Uprated MGB headlight

The sidelights and indicators were in a combined light unit for all chrome bumper cars with the sidelight sitting on the farthest part of the vehicle and the amber indicator next to it. This sidelight and indicator combination went from 1962 through to 1974. A minor change was the position of this lamp as it moved nearer the front grille for all 1969 models onwards.

You will find some countries had the amber lens white, which was mainly for the early North American cars but also found its way into Italy. The North American cars also had the sidelight lenses in full amber colour from 1967, and from 1970 a side repeater was fitted to the front wings again for the North American cars, that were very practical but lost the fluid line of the MGB’s profile. At this time a red rear lamp was installed on the rear wing just in front of the rear light cluster for the same export market.

MGB side and indicator light

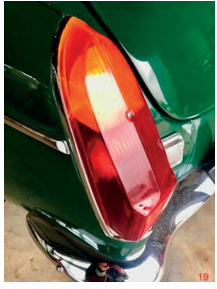

The rear light units for all early cars from 1962 – 1969 had a four-piece design, the back plate bolted to the vehicle, and a chrome surround held the two- piece lenses in place, the top lens for the amber indicator and the bottom lens for the rear lights and brake light. The North American version saw the full light unit in red for both indicators and rear lights.

From 1969 the rear light unit changed to a more angular-looking piece, which was a sturdier rear lamp with a single rear lens, which again was split, for indicator and rear/stoplights. This style of rear light lasted until the end of production, but the actual shape of the shell allows either style of light to fit. Yet again the rear lights for the North American cars had the amber section moved to the bottom part with the red portion at the top.

Both styles of rear light units

DETAILING THE REAR LIGHTS:

The number plate lamps on the MGB started life on the rear over-riders, this is where they remained for most of the production run, in 1974 they were moved onto the bumper itself using the same style of domed cover lights but fitted directly under the number plate.

The North American cars did see another variation when split rear bumpers were used, these were similar to the MG Midget, which existed for only one year during 1970 – 71 and then they reverted back on the over-rider. After 1974 the number plate lights were again installed on a backing plate for the number plate. When the rubber bumpers took over the over-riders were removed so a new way to illuminate the plates was used. The new lamps were all chrome but changed in 1976 to an all-black design.

Rear number plate lamps on the over-rider

Later style lamps fitted to number plate brackets, lower unit is USA style

Reversing lights appeared in March 1967 for the first time and became standard on all models. These square-shaped lights fitted in the rear panel on either side of the rear number plate at the furthest point towards the rear wings and the panel was pressed out for the light and lens to sit in.

Reversing light

Rear fog lights were not a legal requirement during the ’60s and ’70s in the UK, so no provision was made for them, but as laws changed, the need for fog lamps surfaced. This prompted a pair of red Lucas lights to be fitted under the rear bumper to satisfy the new regulations, from June 1979 and for the remainder of the MG’s limited run thereafter.

Rear fog lights fitted below the rear bumper

WINDSCREEN WIPERS

A Lucas motor initially operated the MGB Roadster wipers that moved the 10″ blades 106 degrees across the front screen. The GT had slightly longer blades at 11″ to clear the higher windscreen with a bigger sweep of 115 degrees. The motor itself was a single-speed square-shaped unit operating the cable that in turn moved the wiper rack to turn the wheel boxes that the actual wiper arm was mounted onto (it sounds more complicated than it actually was). This style of motor was used until 1967 and was on all GHN3 cars. The GT had a single-speed motor from 1965 until 1967, but this was the more modern-looking round motor. From 1967 both Roadster and GT had the same style of wiper motor fitted and did look identical but had different drive gears that altered the sweep of the wiper blade. A two-speed motor was next on the upgrades list, which helped clear the screen when caught in heavy rain.

It is worth noting that the wiper’s arms and blades changed, the early cars had a silver polish finish and were narrow in design with a hook that clipped the arm to the blade up until 1967. Later a more robust push-in clip system was used; this improved the connection between the arm and blade but was still a narrow design. Wider blades and arms were later used from 1968 onwards and again in a bright finish until they decided to fit matt black arms from August 1972 retaining the broader style.

All GT cars had two wipers but the MGB Roadster destined for the North American market was fitted with three wipers from 1969 onwards and 1970 onwards for other export markets including Germany, Sweden, and Norway.

It was a good idea and did help clear the windscreen efficiently in bad weather; the only downside is the front area could look quite busy and cluttered with the extra wiper arm and blade. The UK Roadster was always equipped with just the two wipers.

Wiper motor types

Wiper blades for both Roadster and GT

Silver finished wiper blade and arm

Other electrical items of note are the fitment of heated rear screens on the GT, it was an option from 1966 onwards and became standard from the 1972 cars.

Heated Rear Screen

Lastly, the Lucas 9H horns; or I should say horn, originally had just one high note fitted from the factory, a low note horn was an option but from 1970 twin horns were used. In 1974 Mixo horns were fitted until production ceased taking over from the Lucas 9H horn. These were using angle brackets behind the front grille in front of the radiator.

Horns

Horn fitted to the car