MGB – To B or not to B?

Chapter 9

![]()

Hoods, Tonneau Covers and Exterior Items.

The pack-away hood was the first style of hood, it was reasonably fiddly to remove and re-fit, however, and when taken off the car had beautiful, uncluttered flowing lines. No signs of a hood and frame as they were both stored in the boot area, taking up some luggage space instead. The pack away hood had a two-piece frame that connected to form the primary hood support, the header rail attached to the vinyl hood, and clamped to the windscreen frame.

The frame, when split, could be neatly placed into a storage bag and placed in the boot area, the hood then folded up and stowed away with it. The rear of the hood was fastened to the body by a retaining bar that was slotted through the hood below the screen; it slid under two teardrop-shaped retainers on the back panel. The hood was attached using lift- the-dot pegs with four on either side of the rear deck and a clasp on the front just behind the “B” post for the hood to clamp onto. It was an interesting design and remained with the MGB until 1970. During the same period, an upgrade was offered as a factory option instead of the pack-away frame.

It was a folding frame that was fixed to the same points on the windscreen with the mounting points behind the seats.

It now lived in the rear compartment, this grey- coloured frame folded onto itself into the back, you did have to watch your fingers while folding this hood.

Finally, in 1970 the black folding frame, designed by Michelotti took over. It had a much simpler process and was more comfortable to operate, many people often unclamped the front screen clasps and pulled the hood back without removing the rear bars and clips, this was simpler but caused creases in the rear screens and led to eventual cracking, users following the correct folding procedure would ensure the hood lasted without the need for premature replacement.

2 types of hood frames

Hood mounting on the B post

The hood with glass rear screen laid loose onto the car prior to full installation.

The hood came in a material called Everflex leathercloth, initially available in blue, green, red, or grey, during summer 1963 black hoods were gradually introduced until December 1966 when coloured hoods were discontinued. From then on all hoods were supplied in black.

The only alteration to the hood was in 1976 when it was modified for a zip-out rear window that proved to be a popular option for the North American market.

As with most convertibles, the hoods were never totally watertight, the later design did improve things, but there was always the potential for a few drips on your knee coming through should you get caught in some torrential rain.

A popular option was a tonneau cover; these came in two varieties; one was a full cover that went over the entire cockpit of the car when the hood was folded. The other is a smaller half-tonneau or hood cover as it is known, it merely covered the rear portion of the vehicle hiding the folded hood making it look a lot neater.

Full tonneau cover

The Full tonneau used the same fittings as the hood at the rear and the front attached to pegs located on the front scuttle panel above the dashboard.

The full tonneau cover came with a zip halfway across to enable the driver to use the car without the need for removing the cover and still have the passenger side protected from the elements.

Initially available in black, red, and blue but 1966 saw them all become black as standard. The full cover changed to suit the seats and which side the steering wheel was on, early cars were all non- headrest tonneau covers. With the headrests option, the full tonneau was fitted with two pouches to slide over the headrests with different tonneau covers for both D-type and smaller later headrests. They all came with a pocket for the steering wheel to sit in. The tonneau was offered as an optional extra until 1973 when it became part of the standard equipment on UK cars.

Another tonneau cover

The hood cover was first used in 1970 when the black folding hood frame was fitted and again utilized the same fixings as the hood at the rear.

Hood cover

A hardtop was an option from 1963; many cars were sold with the hardtop to make it a good all- year-round car. The hardtop was supplied in standard black from 1966; before that, it was provided in a whole host of different shades including red, old English white, blue, grey, and black. The design hardly changed and was made from fibreglass with a glass rear window and two Perspex rear quarter lights fitted in aluminium frames with the same trim around the doorframes.

It was attached to the car using the same fixings on the windscreen surround and with two mountings rear of the seats in the same position, the hood frame is mounted with a long bolt through a locating bracket, which allowed you to clamp it down securely. They were never the most natural things to fit and line up and not a job you would do regularly, but it made the transition from an open- top sports car to being used in all weathers.

Today, there are other variations instead of the factory hardtop and with different finishes from

more rounded styles to the Bermuda hardtop which has gained quite a following over the years with its very light and airy feel.

Different style of hardtops.

The MGB GT was not offered with a sliding sunroof from the factory. Still, it is believed that many dealers offered the fitment of these, which gave a substantial open feel to the GT model, often referred to as a Webasto roof as this was one of the leading manufacturers of this type of sunroof along with Britax and Weathershield that were both popular brands. The full-length fabric roof was fitted into an aluminium frame, which the vinyl section of the roof could run along and slide back.

At the front, a large handle pivoted to lock itself in place with a wind deflector which lifted up to help prevent too much buffering and wind noise. It gave another option for buyers who maybe didn’t want a full open-top sports car and liked the space the GT model offered but with some added fresh air.

Webasto roof fitted to the car.

Quarter Light Units

The quarter light units on the first pull handle MGB Roadster were unique to that model; they operated in the same way. Still, due to the design of the doors, they were attached to the door frame by two bolts underneath the quarter light much the same as the later cars.

However, they did not have the two forward bolts as there was no front leg of the quarter light, only extra fittings on a securing plate which sat on the inside of the door, attached to the inner skin to stabilise it.

The quarter lights changed on the Roadster in 1965 when the doors changed over to the later style quarter lights with a front leg for extra strength and stability. The quarter light handle that was used to open the glass section was curved, to begin with on both GT and Roadster cars. In 1969 the handle to open the quarter light window became a straight and flatter style that remained until production ceased. The material used initially for all the quarter lights was chrome-plated brass, in 1973 it was upgraded to Stainless steel.

Quarter light fitted to the car

Minor changes occurred to the windscreen frame, but the whole shape and size remained the same. The central support rod was fitted in chrome until 1968 then a satin finish was used. The rear-view mirror clamped to the centre rod up to 1969; these mirrors were recognisable with a gold backing finish until more plastic versions were used.

From 1969 onwards they were fitted to a mounting plate above the rod that made them somewhat more stable and less prone to wobble and vibrate like the earlier type. Sun visors were not fitted originally; so all early windscreen frames have no mountings for these and were not fitted as standard until June 1976 when they were rolled out on all Roadster models. The MGB GT had sun visors fitted from the beginning starting in 1965.

Sun visor on a GT

The glass used for the Roadster windscreen was clear laminated glass all the way through till 1972 when they introduced small cutaways in the corners of the glass. The GT windscreen glass retained the same shape throughout as the body shape around this section never changed, but the tinted glass was offered as an option, this was made standard on the MGB GT V8. The door glass and rear quarter glass were also tinted for the GT V8 model, not just the front screen. It was a subtle green tint, which just gave the look of the car an added edge over the standard model and was, of course, useful on a warm, bright day.

Front windscreens of the GT

MGB Boot Area

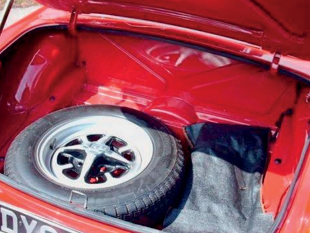

The MGB Roadster had a very usable-sized boot area (or trunk if you live in North America). Inside this space, a spare wheel was installed along with a tool kit.

The spare wheel sat slightly offset to the left and was clamped down to the boot floor by a long bolt with a retaining clamp at the top to stop the spare wheel from moving or bouncing around in the boot.

The wheel clamps altered depending on the wheel it was clamping; the method remained the same, but often the length of the clamp and the size of the retaining section changed to suit the wheel in question.

Spare wheel and tool kit in Roadster boot area

To enable the driver to change a wheel, the car came with its own vehicle jack and tools to remove the wheel and replace it with the spare if needed. The jack supplied slotted inside the jacking point on the side of the vehicle; it was positioned halfway along to be able to lift the full side of the car.

It was painted red and had a handle that you would wind to operate the mechanism. This was updated in May 1973 to a similar design, but even more durable, they were supplied by King Dick Jacks until 1974 when the Metallifacture jack was provided, it was painted black but worked the same way.

Boot area in a Roadster with spare wire wheel

As well as the jack, the kit also consisted of a copper-headed hammer to use for cars fitted with wire wheels, you would simply hit the eared spinner until it started to loosen and spin unless your vehicle was equipped with the octagonal nuts which required a wheel spanner designed to slot over the large nut which you hit instead to loosen it.

Some cars were fitted with this style for safety as the eared spinner did protrude past the bodywork

and all export cars had this type of octagonal nut installed. Steel wheel cars were supplied with a simple wheel spanner to remove the wheel nuts and vehicles equipped with the disc wheels and hub caps also had a lever to aid the removal of the cap to avoid damaging it. The wheel spanner did change depending on the wheels fitted to the car.

All these items were packed away in a PVC bag that was felt coated with a flap at the top and could be secured safely into the boot area; later cars ended up with a fundamental PVC bag to house the tools

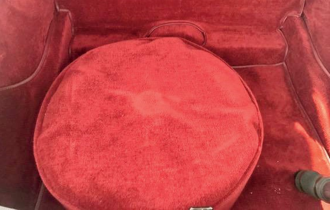

Carpeted boot area with matching spare wheel cover

The boot area was simply finished in body colour with no carpet fitted although many people today have started to carpet the boot area that enhances the look and also helps to deaden the sound.

The GT tool kit was identical, but the spare wheel was located under a wooden board that hinged behind the rear seat and lifted up exposing the spare wheel and tool kit, but the board levelled everything out in the rear luggage area.

It was fastened at the rear with two Dzus fasteners that had a circular-shaped handle you could lift and twist to lift the board. This board changed in 1973 as it went from a two-piece to a single board that hinged with a round cut-out for extra clearance for the spare wheel clamp.

This board was painted black and covered in carpet to match the rest of the trim. The GT also had two small areas behind the rear lights where small items could be stored, again these were carpeted sections.

Optional Extras and Accessories.

Some additional items over and above the standard car were available from the point of order so became factory-fitted options. At the same time, other things were an option direct from the supplying dealer.

These are the items that you could specify and be classed as factory-fit options.

Wire wheels, standard painted 60 spoke wheel; the chrome-plated version was available until June 1971.

Rostyle wheels chrome plated were offered in the early ’70s, this option was from 1970-76.

Whitewall tyres were a fashionable addition, especially for the American market that was offered throughout the production; the UK dropped them from the options list in October 1969.

Tonneau covers were a standard offering from 1972 for the UK market but varied on export models. They were offered as a factory-fit item before 1972.

Wing mirrors are quoted as a factory-fit option up until 1965 when this became a dealer-fit option. The wing mirrors were quite ineffective in use, although they looked nice, the rear visibility was limited. Hence, door mirrors replaced these and were standard on all home market cars from the period 1974 until 1977 when they reverted to a single door mirror on the driver’s side from 1977 – 1980.

Oil coolers were standard fitment on all export cars but optional on the UK version until 1964.

The automatic gearbox option was offered from 1968 to 1973, but because of the lack of demand, this was dropped.

The brake servo unit was optional on the UK- supplied cars from 1970, but the V8 had this as standard and was rolled out in 1973 on all vehicles as standard fitment.

Heaters were not a standard fit on home market cars, although you will likely find one on nearly every MGB, it was offered as an extra but most people living in the UK would almost certainly take up the opportunity to have some form of heating in their car. It officially became standard in October 1968 but was fitted on all export models unless they were being shipped to a particularly hot climate; finally, they were standardised on all export cars from 1975.

Overdrive was only standard from the 1976 model but offered as an optional extra from January 1963, it was fitted on the GT V8 but not rolled out on the North American cars where it remained optional from the factory.

Hardtops were available from the factory at the start of 1963 and were still available up to 1976; after this, dealers were able to supply if needed.

Map pockets could be fitted to the left side of the passenger’s foot well and were standard on the GT model and covered in carpet to match the colour of the interior trim. They were offered on the home market Roadsters until 1971, but the North American market had them fitted as standard from 1967.

A grey folding hood was a factory option instead of the pack-away style until 1970 when the black folding frame took over.

A luggage rack was offered from the factory until 1965 when it became a dealer-fit accessory.

The rear seat cushion option was given to have the rear compartment fitted with a seat cushion on the MGB Roadster the same as the GT had fitted, this would be trimmed in the same style as the front seats but discontinued in 1969.

Car radios were available to specify from the factory before they became a dealer option.

Fog lamps or driving lamps could be factory-fitted for UK cars up until 1963 and 1965 for export cars before being destined to be a dealer-fit option after that.

A cigar lighter was an option until made standard in 1972 on the GT model and then in 1973 standard on all Roadster models apart from the North American cars which saw this become standard on the 1968 model cars. An ashtray could be installed on the transmission tunnel just between the gear lever and the speaker console; it was made standard on home market cars from December 1969 and earlier in 1968 for all vehicles designated for export.

Metallic paint was offered only on the GT and in either Riviera silver blue or metallic golden beige with neither colour proving very popular with the majority of buyers.

Dealer fitted items

Over time it became much easier for the factory to build cars to a less complicated specification leaving the dealers to fit more and more accessories, this also gave the dealer an option to generate more business and up-sell when the car was sat in the showroom.

A list of the most requested options is detailed below and many we will have seen fitted to MG’s over the years

A badge bar was offered for any additional badges to be added to the front of the car.

The Locking petrol cap, as the prices of fuel crept up, the value grew, and an increase in theft began.

A chrome luggage rack was already mentioned, and this was a popular choice to carry that picnic basket on, the North American cars were fitted with a different style than the UK that had four mounting brackets at each corner and did look rather neat.

Rubber floor mats were available in a choice of colours, black, red, grey, green, and blue; today most rubber floor mats are supplied in black.

Touch-up paint is always popular to ensure the correct colour is used in the event of stone chips. Mud flaps were a popular dealer extra as when these cars were initially sold, they were everyday cars; they needed this extra protection.

Wheel trim rings that fitted around the outer edge of Rostyle wheels, looked nice but fitted very snugly, so removal of them often caused damage and scratching of the painted wheels.

The dealers offered many other items; they ranged from license holders to different styles of exterior mirrors and driving lamps. The North American cars had an even bigger list on offer, as the market for accessories was influential in the US, they were offered striping kits to wood rim steering wheels as well as additional racing equipment.

Overall the standard cars were good value, but any car manufacturer and most dealerships offer the extras and accessories list to help you personalise your new vehicle. MG and British Leyland were no different and made the picking of additions an easy task for potential buyers.